Some Ideas on Premier Aluminum Llc You Should Know

Some Ideas on Premier Aluminum Llc You Should Know

Blog Article

Getting The Premier Aluminum Llc To Work

Table of ContentsSome Ideas on Premier Aluminum Llc You Should KnowPremier Aluminum Llc for DummiesOur Premier Aluminum Llc DiariesFacts About Premier Aluminum Llc RevealedThe Greatest Guide To Premier Aluminum Llc

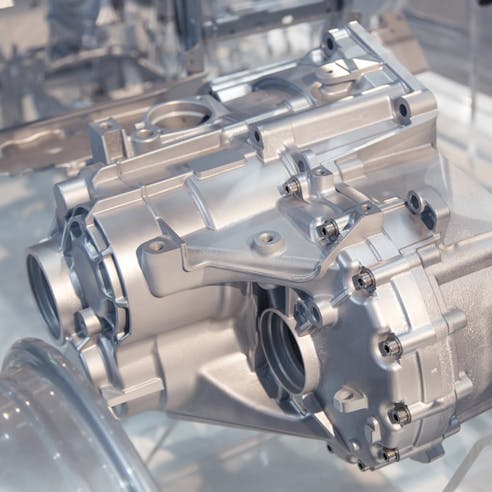

When choosing a light weight aluminum shop for your manufacturing needs, it's critical to examine numerous elements. One of one of the most critical aspects to think about is the experience and competence of the factory. Choosing a shop who has the right expertise of the light weight aluminum casting procedure, and the profile to reveal for it, aids to have an effective result for your job.Having the experience and industry understanding to craft your spreadings for optimal manufacturing and quality outcomes will enhance the job. Making aluminum spreading calls for a facility collection of processes to achieve the ideal outcomes. When determining on a new light weight aluminum shop to companion with, ensure they have substantial market experience and are knowledgeable about all aspects of the aluminum spreading process: layout, manufacturing, material evaluation, and item testing.

The foundry should likewise have a tried and tested record of providing outstanding products that meet or exceed consumer expectations. Quality assurance should also go to the top of your checklist when selecting an aluminum foundry. By dealing with a certified shop that adheres to the criteria for quality assurance, you can secure the stability of your item and ensure it satisfies your specs.

Getting My Premier Aluminum Llc To Work

Numerous components that extremely made complex forms can be produced using this procedure. Before you start browsing for a reliable light weight aluminum die wheel, there are some crucial things that you require to do.

You have to ask on your own what type of light weight aluminum die castings you require. After identifying what you call for, you have to specify the specifications of the aluminum pass away castings you need.

After having this information, you can begin investigating light weight aluminum die-casting makers. You can do this by just inputting the keyword" Aluminum die casting makers" on the Google search engine.

Several of the questions you require to ask yourself are whether they have actually experienced and trained operators, how much time their organization has actually functioned, or if they have some success. You can commonly obtain the response to these inquiries from the supplier's website. You can investigate various other internet sites or external sources to validate if the information given on the producer's site is genuine.

The Ultimate Guide To Premier Aluminum Llc

Another thing you need to think about is the producer's capability to generate aluminum die-casting items. Simply put, the volume of products the producer can produce at a given time. Some of the critical concerns you need to ask on your own are whether the manufacturer can generate a greater quantity or can the producer fulfill your demands.

(https://www.dreamstime.com/garymartin53403_info)What happens if your company needs 10,000 items of particular device parts from the maker within one month? You got this amount; nevertheless, the producer can just produce 5000 items of these device parts within one month (Aluminum Casting). Therefore, you will not be able to receive the quantity that you buy promptly

The Premier Aluminum Llc PDFs

For this reason, it is necessary that you need to inquire if the manufacturer is applying an internal tooling procedure. Furthermore, you need to ask the supplier just how much the price of in-house tooling is. Maintain in mind that the in-house tooling official website process, which allows you to produce distinctive layouts and shapes can be an additional cost.

This aspect directly associates with the maker's production capacity. You need to search for a manufacturer that can make sure quicker shipment of items. This must be done in such a means that top quality requirements are kept. This can guarantee that you can obtain your items on time, and you can stay clear of missing out on those important company possibilities.

This means that there are several choices that you can select from. Today, client demands go on altering. It appears that clients are searching for an excellent combination of high quality, cost-effectiveness, and longevity. That is why it is greatly advised that you should select a supplier that can create different kinds of aluminum die-cast products.

Getting My Premier Aluminum Llc To Work

Usually, these light weight aluminum die-casting items will need some decors, machining, or ending up touches. Having this in mind, you ought to try to find a producer that can carry out a range of second finishing jobs once pass away spreading is done. Some instances of completing procedures include Chromating, CNC Machining, Sandblasting, Powder finish, Anodized, E-coating, Damp painting, Plating, and a lot more.

Die spreading is one of the most cost-efficient, accurate, and protean manufacturing procedures in the globe moment. The procedure includes fitting molten essence, under stress, right into a suitable die (planet), and formerly strengthened it can be ejected and completed (if needed) in a range of methods. Report this page